[1].

Click here to

watch the movie.

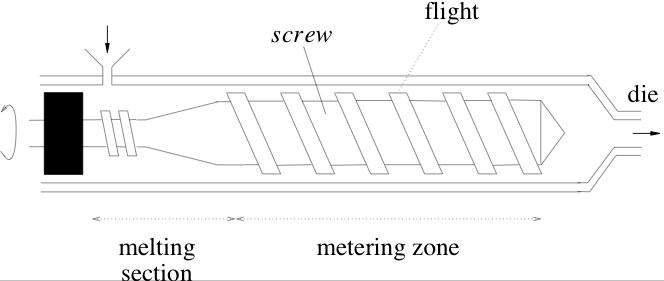

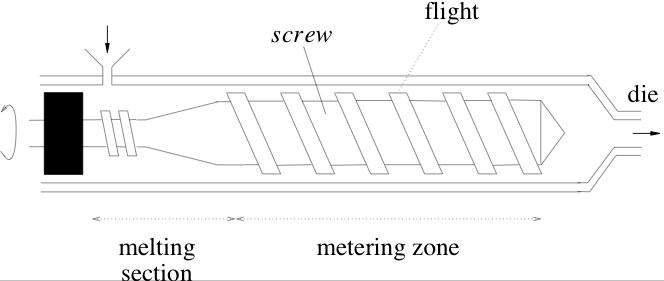

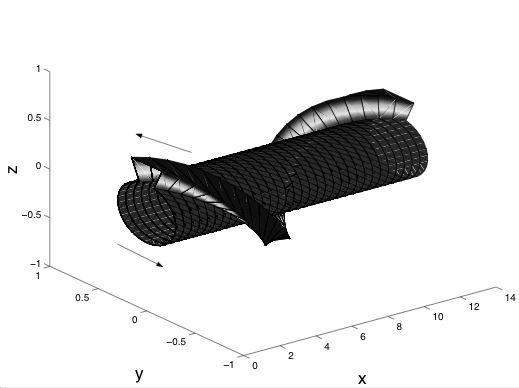

A

three dimensional view of the screw

geometry used in the simulation is shown below (the outer barrel is not

visible). The arrows indicate the counter-clockwise rotation of the

screw.

1. M. J. Stevens & J. A. Covas (1995), Extruder principles and operation.

Chapman and Hall.

2. M. G. Blyth & C.

Pozrikidis (2006), Stokes flow through a

single-screw extruder. AICheJ, 53(1), 69-77.

3. C. Pozrikidis (2005),

Introduction to Finite and Spectral Element Methods using Matlab.

Chapman and Hall/CRC.